WHILL

Highlights

Challenge

WHILL needed a flexible, efficient way to update and manage connected prototypes remotely while minimizing communication loads and conserving battery power.

Solution

By using Soracom Air for connectivity and Soracom Beam for protocol conversion, WHILL streamlined device management, reduced manual intervention, and optimized data transfer.

Impact

Development time was shortened, battery usage reduced by more than 30%, and WHILL gained a foundation for safer, more connected mobility experiences.

A new era of mobility

WHILL is a personal mobility device designed to go beyond traditional wheelchairs. With a sleek design, intuitive controls, and smooth ride, WHILL delivers independence and style to users who rely on it for everyday mobility. But the team behind WHILL knew that connectivity could take the device even further, unlocking advanced features and smarter services.

Integrating IoT into WHILL had been under discussion for some time. The team envisioned features such as remote diagnostics, data-driven safety enhancements, and personalized rider experiences. By connecting WHILL to the cloud, they could transform it from a standalone mobility device into a platform for continuous innovation.

However, the team came from hardware backgrounds in fields like cameras and mobile phones, with less experience in telecommunications and cloud infrastructure. On top of that, WHILL’s battery-powered design made every byte of communication matter, creating a unique challenge for bringing IoT functionality onboard.

The challenge of flexible development

When developing new features, WHILL’s team relied heavily on prototypes and demo units. These devices were often shared with early users, providing invaluable real-world feedback during the development process. But making backend changes required engineers to manually update each prototype in person—an inefficient and time-consuming step that slowed iteration.

This lack of flexibility meant it could take weeks to test new ideas at scale. Every system reconfiguration demanded physical visits to end users, leaving the team without a way to adjust devices dynamically once they were in the field. For a company focused on speed and innovation, this was a major bottleneck.

WHILL needed a system that would let them manage prototypes remotely, update settings on the fly, and streamline testing with real users. At the same time, any solution had to be designed around the strict energy constraints of a mobility device that depended on long-lasting battery performance.

Smarter connectivity with Soracom

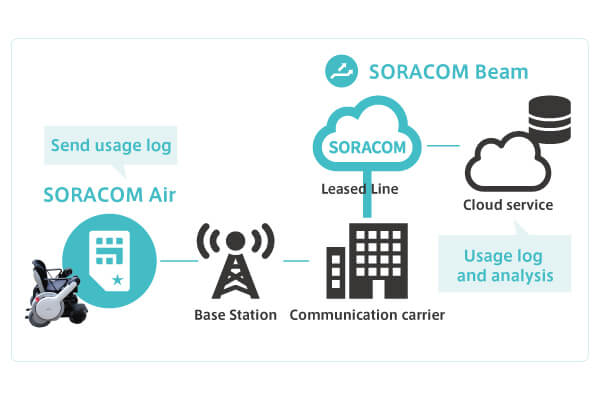

To solve this, WHILL adopted Soracom Air for connectivity and SIM management, enabling devices to start and stop data communication remotely. By leveraging the Soracom API, WHILL could manage communications programmatically during manufacturing and shipping, reducing manual setup.

Minimizing data loads was equally important. With Soracom Beam, WHILL was able to convert lightweight UDP and TCP traffic into secure HTTPS requests in the cloud. This allowed them to send only small packet sizes from the device, with Soracom handling the heavy lifting of secure transfer to WHILL’s backend servers. The result was both efficient and secure communication.

Together, these services transformed development. Instead of requiring engineers to manually update each device, WHILL could make changes in the cloud and apply them seamlessly across the fleet. This reduced wasted time in the field, allowed more agile testing cycles, and protected device battery life.

Why Soracom?

The decision to use Soracom was driven by both efficiency and reliability. By shifting routing and conversion tasks into the cloud, WHILL was able to significantly cut the workload on the device itself. This approach led to a 30% reduction in battery consumption, a critical advantage for riders who depend on WHILL throughout the day.

Soracom’s flexibility also simplified system management. When content or server configurations changed, WHILL’s team could easily update routing in the cloud without touching devices in the field. This ability to toggle settings remotely made their development cycle more dynamic and responsive.

WHILL also discovered value in Soracom’s built-in identifiers. Instead of transmitting device serial numbers, an unnecessary use of bandwidth, they used IMSI IDs from each SIM along with timestamp features to identify and validate devices. This small change eliminated redundant data transfers and further optimized communications.

Future Plans

Looking ahead, WHILL plans to extend connectivity to new features that will enhance both safety and convenience for riders. By uploading GPS coordinates, battery levels, and diagnostic data, WHILL can monitor performance in real time and alert users to potential issues before they become problems.

The team also sees opportunities to use data to improve user experiences. From optimizing routes to providing timely service updates, connectivity will help WHILL deliver a smarter, more personalized mobility solution. These services could further empower riders with independence and peace of mind.

With Soracom as its IoT backbone, WHILL is well-positioned to scale quickly and adapt to customer needs. As the company continues to innovate, its combination of stylish design, intuitive controls, and smart connectivity promises to redefine what personal mobility can be.

Champion in IoT

Connectivity Management

Soracom Named as a Champion for IoT Connectivity Management in 2023 Kaleido Intelligence Connectivity Vendor Hub