K’s Design Lab

Highlights

Challenge

Industrial cutting operations can last hours or days, requiring a way to securely monitor and adjust workflows without staying tethered to the machine.

Solution

K’s Design Lab equipped its 3D-Mill K-650 with Soracom Air for mobile connectivity and Soracom Gate with a Virtual Private Gateway for secure, remote monitoring and control.

Impact

Designers can now oversee and adjust cutting operations in real time from anywhere, improving flexibility, precision, and efficiency.

About: Serious prototyping tools for the 3D modeling age

K’s Design Lab specializes in advanced 3D design, prototyping, and fabrication tools for both professional and industrial users. Their solutions support a wide range of materials and workflows, from vacuum forming to product prototyping and external design, giving creators the tools to bring ideas from digital models into physical form.

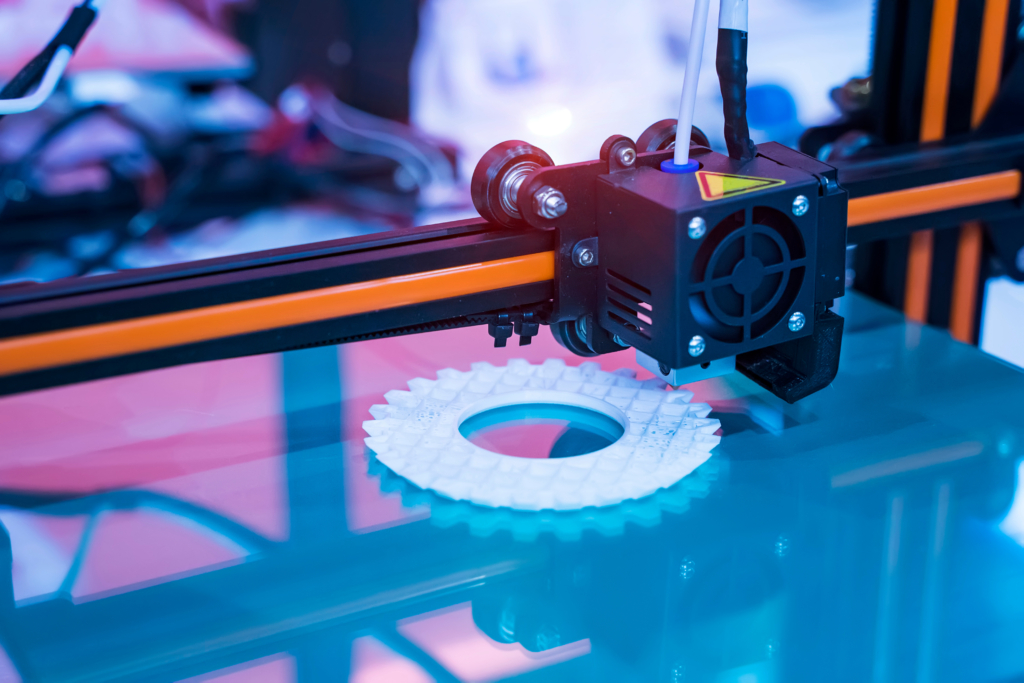

The company’s flagship 3D-Mill K-650 was designed from a technician-first perspective, combining precise cutting capability with the flexibility required in modern fabrication. Once material passes through a 3D printer, it moves into cutting operations, where the K-650 enables free-form curves, fine textures, and high-quality finishes that more closely reflect the original data.

By empowering designers with versatile fabrication equipment, K’s Design Lab has positioned itself as an essential partner for the growing demand in rapid prototyping and advanced industrial model-making.

The Connectivity Challenge: Remote management during lengthy cutting operations

Cutting jobs can vary widely in length depending on size and complexity, sometimes running continuously for hours or even days. During this process, operators typically use a tablet to monitor progress and make adjustments in real time. However, staying physically present throughout an entire job is often impractical or inconvenient.

Without the ability to step away, designers risk reduced productivity and unnecessary downtime. The lack of remote control options also limited the flexibility of the K-650, making it harder to take full advantage of its capabilities.

K’s Design Lab recognized that in order to maximize efficiency, users needed a secure, reliable way to remotely monitor, manage, and adjust the cutting process—without compromising the safety or precision of the equipment.

Solution: Secure wireless monitoring and control with Soracom

To address this challenge, K’s Design Lab integrated Soracom Air into the 3D-Mill K-650, enabling a secure mobile data connection that allowed operators to carry the machine’s controller with them wherever they went. This mobility meant users could remotely oversee the cutting process in real time, without needing to stay tethered to the machine.

The team also developed a custom application that allowed users to personalize their controls for designing, testing, and cutting 3D models. This combination of mobile connectivity and flexible software gave designers more freedom and control over the entire workflow.

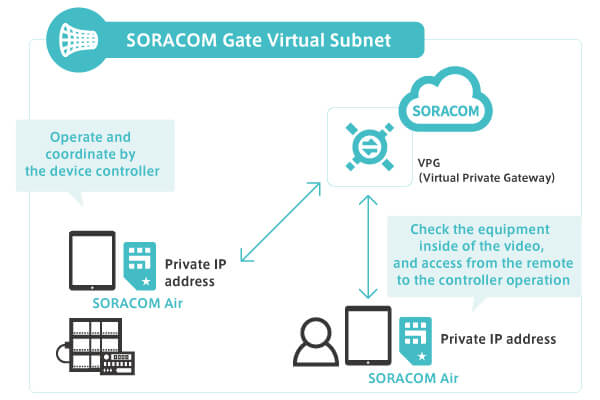

Security was a critical priority. To ensure data integrity and safe access, K’s Design Lab implemented Soracom Gate with a Virtual Private Gateway (VPG). This setup allowed devices using Soracom Air SIMs to operate on the same subnet with private IP addresses, creating a secure channel for communication between tablets, machines, and company servers.

Why Soracom: Balancing flexibility with robust security

For K’s Design Lab, the combination of Soracom Air and Soracom Gate provided the best of both worlds: secure connectivity and flexible deployment. By leveraging Soracom’s cellular services, they avoided the risks of relying on shared Wi-Fi networks and created a system that could be reliably accessed from anywhere.

The use of a Virtual Private Gateway was especially important. It ensured that K’s Design Lab could loan tablets freely to operators and clients, while still retaining secure access to monitor equipment and make adjustments as needed. This protected sensitive workflows without creating unnecessary barriers for end users.

By building their solution on Soracom, K’s Design Lab drastically improved the usability of the 3D-Mill K-650, delivering a more powerful and user-friendly tool for both designers and industrial professionals.

Future Plans: Driving ever-greater manufacturing precision

The rising demand for rapid prototyping and advanced model fabrication continues to push innovation in 3D production tools. K’s Design Lab is committed to expanding its portfolio of precision equipment to help makers, designers, and industrial users translate digital designs into high-quality physical objects.

As manufacturing workflows evolve, the company plans to build on its existing IoT foundation to deliver even greater levels of efficiency and precision. Future developments will focus on accelerating the prototyping process while maintaining the highest standards of accuracy and finish.

By integrating secure IoT connectivity with advanced fabrication technology, K’s Design Lab aims to help customers achieve new levels of creativity, productivity, and manufacturing excellence.

Champion in IoT

Connectivity Management

Soracom Named as a Champion for IoT Connectivity Management in 2023 Kaleido Intelligence Connectivity Vendor Hub