Mitsubishi Heavy Industries

Highlights

Reducing Onsite Risk

MHI’s EX ROVR ASCENT enables remote inspection of hazardous offshore oil and chemical plants, reducing the need for costly and dangerous human presence.

Secure, Scalable IoT Architecture

Soracom Air, Gate, Beam, and Funk provide secure bi-directional communication, protocol conversion, and cloud integration.

Faster Deployment, Long-Term Growth

Soracom’s IoT expertise helped MHI complete the project on time and continues to support expansion into new applications.

The Opportunity: Remote Monitoring for High-Risk Facilities

Operating offshore oil and chemical plants requires constant monitoring, but keeping human inspectors on-site poses significant cost, safety, and logistical challenges. Transporting crews, often by helicopter or boat, is expensive and vulnerable to weather delays, while the work itself can be hazardous.

Mitsubishi Heavy Industries (MHI) identified an opportunity to reduce these risks by developing an autonomous inspection solution capable of collecting detailed operational data without requiring continuous human presence.

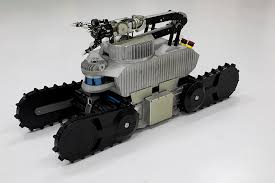

The Solution: The EX ROVR ASCENT

Originally designed in 2014 with Eneos Corporation for nuclear plant inspections, the EX ROVR ASCENT is a fully autonomous, explosion-proof inspection robot now also deployed in oil and chemical plants. Compact at 70 × 45 × 60 cm, it can navigate complex facilities, climb stairs, and operate a pneumatic arm equipped with microphones, multiple cameras, a thermal imaging unit, and a gas concentration sensor.

The robot transmits inspection data, including audio, visual, temperature, and gas readings, to the cloud, where operators can review it in real time. It can operate for two hours per battery charge, with 24/7 coverage possible using paired units.

Future versions are expected to autonomously determine when inspections are needed, further increasing operational efficiency.

Why Soracom: Secure, Integrated IoT Connectivity

The EX ROVR ASCENT required a communications system that could support both remote control and autonomous operation while securely transmitting sensitive industrial data. Rather than build a complex custom infrastructure from scratch, MHI leveraged AWS cloud services combined with Soracom’s IoT platform for end-to-end connectivity and security.

Soracom Air IoT SIMs provide reliable, global cellular coverage. Soracom Gate enables private, bi-directional LAN connections between deployed robots and remote control terminals. Soracom Beam and Soracom Funk handle secure routing and protocol conversion, transmitting telemetry data directly to AWS. The IoT SIMs themselves authenticate and authorize each device.

“We chose Soracom because their wide service area covered all of the countries where we planned to deploy the system, confidential information could be securely communicated through a closed network, and we could rely on extensive support,” said Naoki Mizuno, Equipment Design Section, MHI. “It is very reassuring to have a partner that so thoroughly understands the innermost workings of the EX ROVR ASCENT, and gives us appropriate advice.”

Soracom’s support helped MHI complete the project on schedule while reducing the system’s maintenance burden.

The Outcome: A Safer, Smarter Future for Offshore Operations

With Soracom managing all communication between the robot, remote terminals, and AWS, MHI has streamlined system architecture and positioned the EX ROVR ASCENT for scale.

The success of the project has sparked interest across MHI in applying Soracom-powered IoT solutions to other products. The company is now exploring ways to use deep learning and signal processing on collected data to detect, predict, and eventually respond to anomalies in real time.

“In addition to anomaly detection, we would also like to focus on how we can create more value from the data collected by sensors,” said Mizuno. “The world is shifting toward the cloud, which has the advantage of consolidating data in one place. This will make the use of data more valuable.”

Champion in IoT

Connectivity Management

Soracom Named as a Champion for IoT Connectivity Management in 2023 Kaleido Intelligence Connectivity Vendor Hub