Digitizing Feed Inventory for Smarter Agriculture

Download PDFHighlights

- Taking the Guesswork out of Feed Bin Management - Bin Sentry enables smart, remote inventory management for feed mills using advanced sensor and AI technology, but needed a reliable, scalable way to connect devices deployed in rural, low-coverage areas.

- Reliable Performance Via Smart Connectivity - Soracom’s multi-carrier IoT connectivity, flexible billing, and remote SIM management allowed Bin Sentry to reduce downtime, avoid paying for inactive devices, and scale globally with confidence.

- A Partnership Designed for IoT - In Soracom, BinSentry found a partner who understood the challenges of IoT, and helped to address them with creative solutions that have improved the company's bottom line.

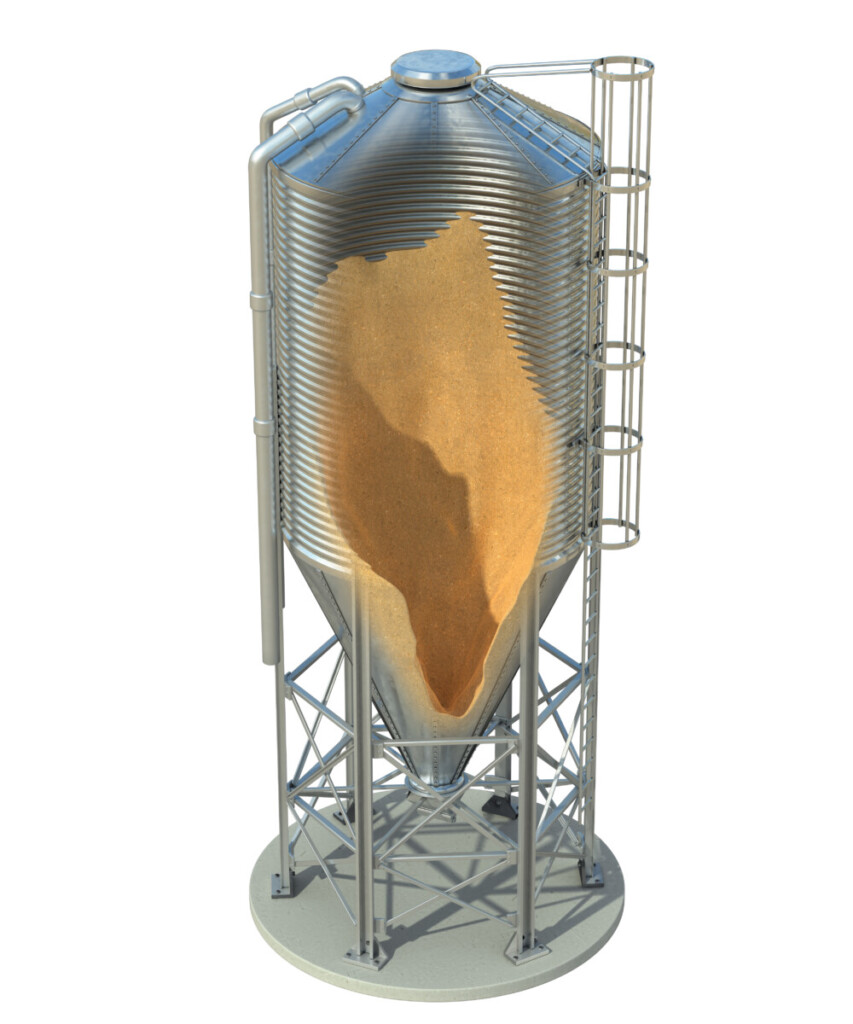

BinSentry is a smart ag company revolutionizing feed management for animal agriculture. With its proprietary sensor technology, the company enables feed mills and vertical integrators to remotely monitor inventory levels in farm bins and large silos. Its flagship devices, including the explosion-proof Pro Sense HD, use near-infrared time-of-flight sensors and AI-powered image processing to produce accurate 3D volume readings – even in harsh, dusty environments. The result? Real-time, reliable inventory data that keeps animals fed, workers safe, and fleets running efficiently.

“We take about a half million total measurements just to get a single volume inside of a bin,” said Nathan Hoel, Co-Founder and CTO. “And that raw data gets processed using AI to deliver a precise reading back to the mill.”

The Challenge: Reliable, Scalable Connectivity in Remote Areas

To deliver accurate inventory data, BinSentry’s devices must transmit large volumes of sensor readings from rural and remote farm sites – locations often underserved by traditional cellular networks. These areas may only have partial or inconsistent coverage, making it difficult to maintain a stable connection for IoT devices – particularly when those devices must operate in potentially challenging weather conditions.

“In rural areas, it doesn’t matter what the coverage map says. You just need access to multiple carriers. If one signal drops, we can’t afford downtime,” said Hoel. “We need as much carrier overlap as possible.”

The challenge is compounded by BinSentry’s device ownership model. Unlike consumer IoT, BinSentry owns and manages its devices end-to-end – from manufacturing and field installation to servicing and redeployment. Devices tested on the assembly line might then sit in inventory or with a technician for weeks or months before deployment. Though the devices are not in use at this time, traditional MVNOs will still charge full data rates.

“We’re managing all these connections, and we build devices that may sit idle for months before deployment,” said Hoel. “But with most carriers, we were paying full price whether we used them or not.”

Even after initial deployment, devices might need to be temporarily taken offline for servicing or refurbishment, before being reinstalled elsewhere. BinSentry needed a connectivity solution that could flex with their operational reality by allowing them to turn connectivity on and off remotely.

“With Soracom, it just works. We don’t have to think about where it’s going or what network it’s on. That peace of mind lets us scale confidently.”

Nathan Hoel

CTO and Co-Founder, BinSentry

The Solution: Flexible, Intelligent IoT Connectivity with Soracom

BinSentry found the ideal partner in Soracom, whose global IoT platform delivered exactly what the company needed: multi-profile SIMs, automatic failover across carriers, and a billing model designed for the realities of industrial IoT.

Unlike traditional cellular providers that lock customers into always-on billing, Soracom allows devices to be activated, suspended, or deactivated on demand. This flexibility has proven crucial to BinSentry’s business model, which requires devices to be tested during manufacturing, paused during inventory or transit, and then reactivated only once installed in the field.

“We were almost paying double what we were actually using, and from an operational and margin standpoint, that was crazy” said Hoel. “When we went to Soracom, not only were they competitive on price, but we were able to turn off everything we weren’t using without having to program it into our own system.”

Additionally, Soracom’s real-time monitoring tools, cloud integrations, and SIM management portal allow the BinSentry team to manage connectivity across tens of thousands of devices without writing custom infrastructure or handling billing manually.

“It was surprising to contrast a group who just doesn’t seem to understand how IoT runs, even though they claim to be selling to IoT, and Soracom, who seems to have built everything up from the ground to work for an IoT company. It was just a night and day difference for us. The billing, the tools, everything was there for us.”

Soracom even helped the team source rugged industrial-grade SIMs that passed microscopic lab testing for durability in extreme temperature fluctuations – a key requirement for devices mounted on hot, sun-exposed feed bins in the summer or sub-zero silos in northern winters.

“They worked with us to source and test industrial SIMs with proper gold plating,” said Hoel. “That level of support was a game-changer.”

Results and What’s Ahead for BinSentry

With Soracom, BinSentry has improved device uptime, mediated wasteful data costs, and streamlined global deployment. Their technical team now spends less time troubleshooting connectivity and more time innovating.

“With Soracom, it just works. We don’t have to think about where it’s going or what network it’s on. That peace of mind lets us scale confidently,” said Hoel.

As BinSentry expands its presence beyond North America and develops new sensing applications, it plans to continue building on its success with Soracom as a trusted connectivity partner.

“Soracom is a partner in our business. When there’s a problem, they’re on the call with us solving it. That’s what we need to grow.”